Main purpose

1. Fully insulated, fully sealed, maintenance free, and reliable to ensure personal safety;

2. Compact structure, with a volume only 1/3-1/5 of the same capacity European transformer; The height is only 1.5, not blocking the line of sight;

3. Adopting a split box structure to avoid contamination of oil in the transformer oil tank;

4. The high-voltage side adopts dual fuse full range protection, greatly reducing costs;

5. It can be used for both ring network and terminal, and the cable head can be urgently plugged and unplugged when the load current is 200A;

6. The box is made of honeycomb double layered composite board, which has both insulation and heat dissipation functions.

7. The low-voltage side can be equipped with an undervoltage controller, which can quickly cut off the low-voltage side composite when abnormal voltage occurs in the system;

8. High voltage oil immersed load switches or SF6 load switches can be automatically upgraded, laying the foundation for achieving distribution network automation.

purpose

Widely used in urban power grid renovation, residential areas and other public places, as well as indoor and outdoor places such as factories, mines, hotels, airports, railways, docks, highways, etc.

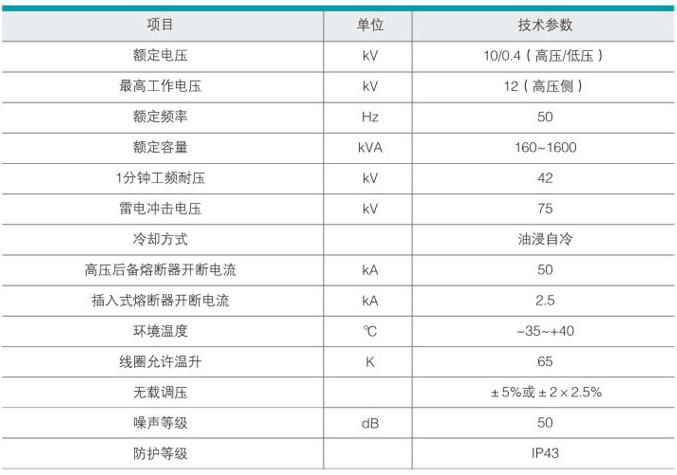

Normal usage conditions

1. Altitude not exceeding 1000m;

2. Environmental temperature: -35 ℃ to+40 ℃;

3. Relative humidity: daily average not exceeding 95%, monthly average not exceeding 90%;

4. Installation location: A place without fire, explosion hazards, chemical corrosive gases, and good ventilation, with a ground inclination angle of no more than 3 °.

Execution standards

This product meets the following standards:

GB/T17467-1998 "High voltage/low voltage prefabricated substations"

DL/T537-93 "Technical Conditions for Ordering 6-35kV Box type Substations"